Hydrogen Production by Methanol Reforming

Hydrogen production by methanol-reforming is the best technology choice for clients with no source of hydrogen production raw materials. The raw materials are easy to obtain, easy to transport and store, the price is stable. With the advantages of low investment, no pollution, and low production cost, hydrogen generation by methanol is the best method for hydrogen production and has strong market competitiveness.

The methanol-reforming hydrogen production technology developed and designed by Ally Hi-Tech has reached the advanced international level after decades of continuous research and improvement, Ally has obtained a number of national patents and honors.

Since 2000, our company has developed and designed the technology of methanol reforming and hydrogen production, which has reached the advanced international level. At the same time, we have successively obtained three national patents, and compiled GB / T 34540 “Technical Requirements for Methanol Reforming and PSA Hydrogen Production System”. Ally is a professional hydrogen production company with a high market share, 60000nm3 / h single set scale, 3.3Mpa pressure, and better catalyst R&D(the sixth generation) in the world.

Technology Characteristics

● Flameless, hot oil furnace could be deployed adjacent to reformer

● Simple process, low investment, short payback

● Less NOx, lower temperature in the furnace

● Recovering off-gas, less methanol consumption

● Mature technology, safe and reliable operation

● High Automation

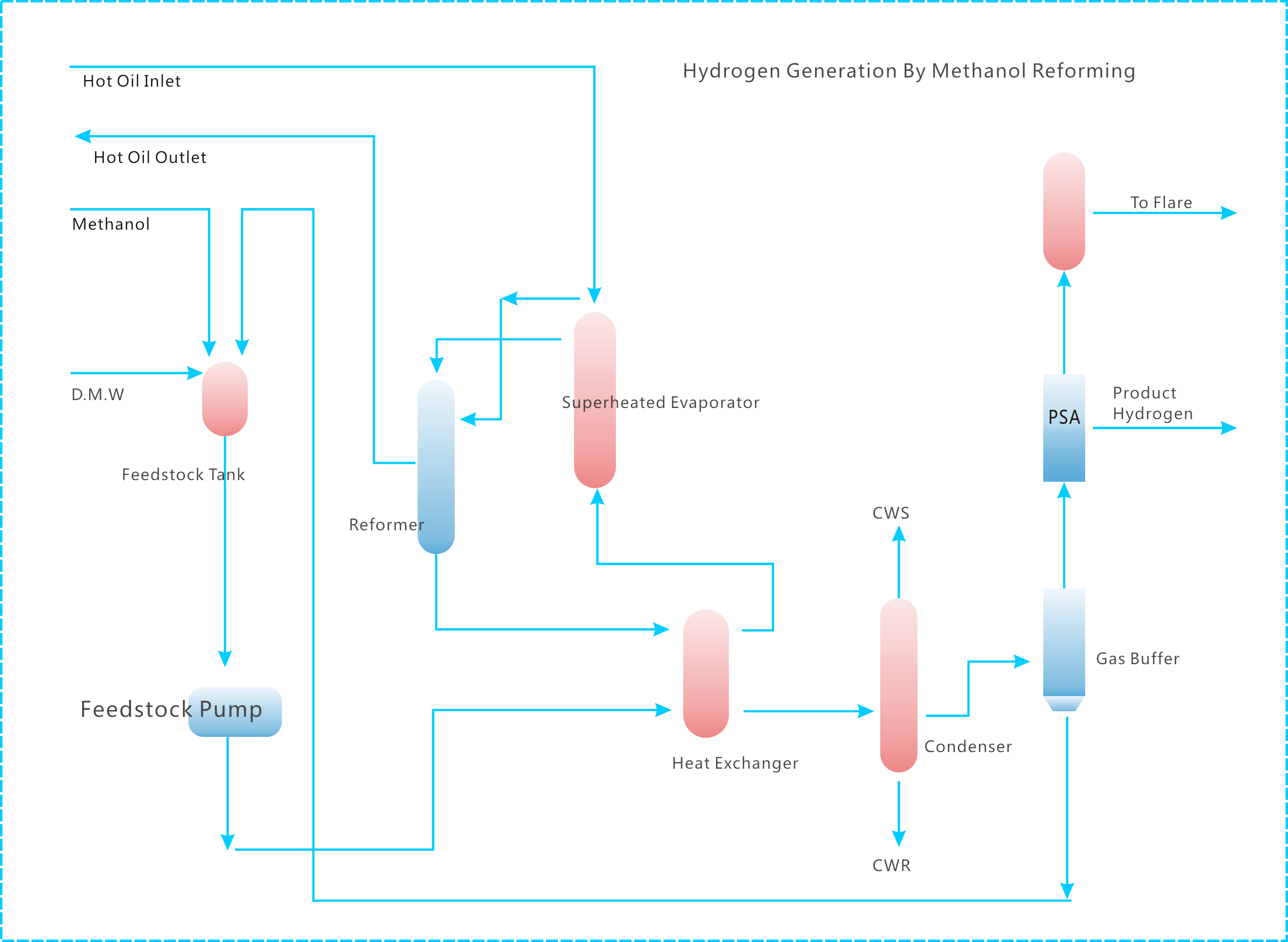

Technical Process

The mixture of methanol and de-mineralized water, after pressurized, evaporated, and superheated to a certain temperature, is fed into a reactor, where the reforming gases including H2, CO2, CO, etc. are formed under the action of the catalyst. The mixed gas is treated through the purification technology of PSA to get high purity hydrogen in one cycle.

Main Technical Parameter

| Plant size | 50~60000Nm3/h |

| Purity | 99%~99.9995% (v/v) |

| Temperature | ambient |

| Product pressure | 1.0~3.3MPa(G) |