Hydrogen Production by Methanol Reforming

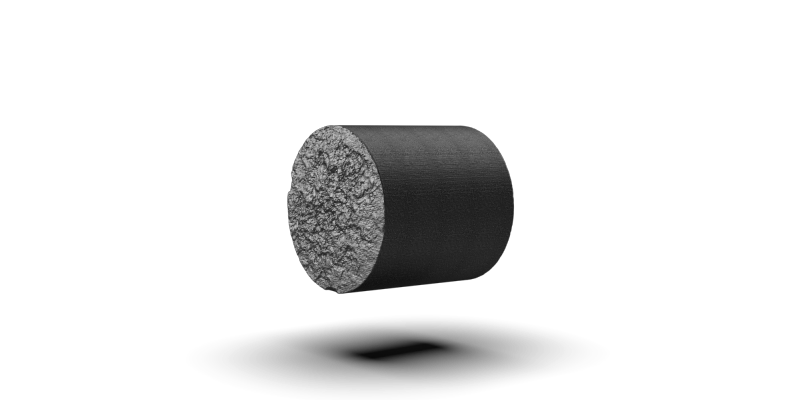

1. KF104/105 Methanol Reforming Catalyst for Hydrogen Production

Copper zinc catalyst with copper oxide as the main component. The Methanol reforming catalyst for Hydrogen production has large effective copper surface area, low service temperature, high activity and stability, and is in the leading position of the same series of products at home and abroad.

Specification: 5 * 4~6mm column

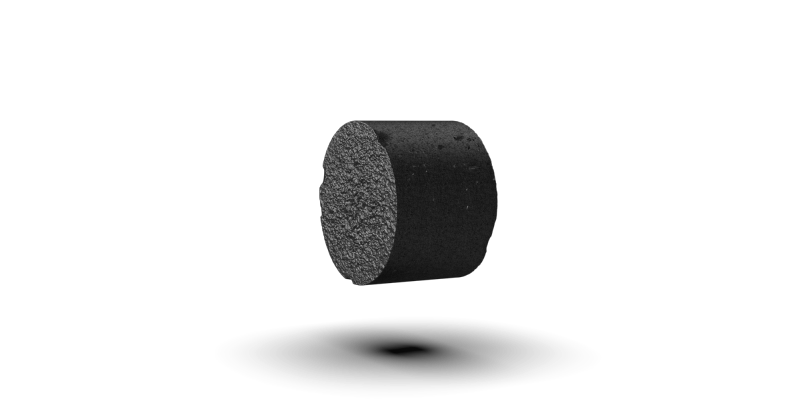

2. B113 High (Medium) Temperature Shift Catalyst

An iron chromium catalyst with iron oxide as the main component. The catalyst has low sulfur content, good sulfur resistance character, high activity under low-temperature, low steam consumption and wide temperature range. It is applicable to synthetic ammonia and hydrogen production units using coal coke or hydrocarbons as raw materials, as well as the shift of carbon monoxide in methanol synthesis and the shift process of city gas.

Specification: 9 * 5~7mm column

3. Chromium-Free Wide Temperature Water-Gas Shift Catalyst

A chromium free wide temperature water-gas shift catalyst with iron, manganese and copper oxides as active metal components. The catalyst contains no chromium, is non-toxic, has low temperature to high temperature shift activity, and can be used at low water-gas ratio. It is suitable for adiabatic water-gas shift process and can replace Fe-Cr catalyst in hydrogen production process from natural gas.

Specification: 5 * 5mm column

Hydrogen Production by Natural Gas

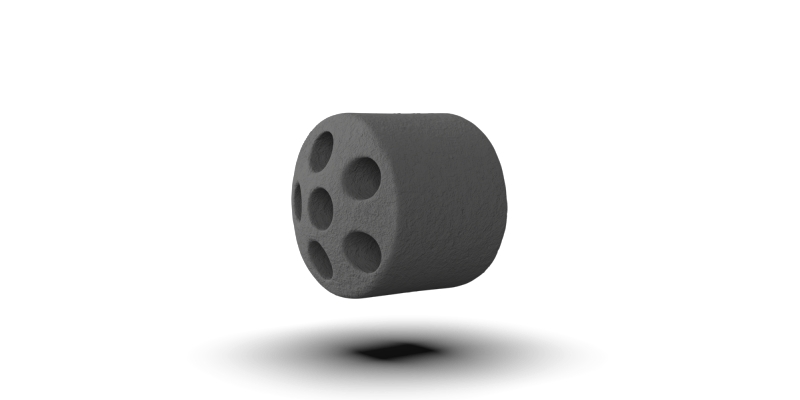

4. SZ118 SMR Catalyst

A nickel based sintered reforming catalyst with aluminum oxide as the carrier. The sulfur content of the catalyst is extremely low, and there is no obvious sulfur release during use. It is applicable to the primary steam reforming(SMR) unit using methane based gaseous hydrocarbons as raw materials (natural gas, oilfield gas, etc.).

Specification: Double arc 5-7 hole cylindrical, 16 * 16mm or 16 * 8mm

Desulfurizer

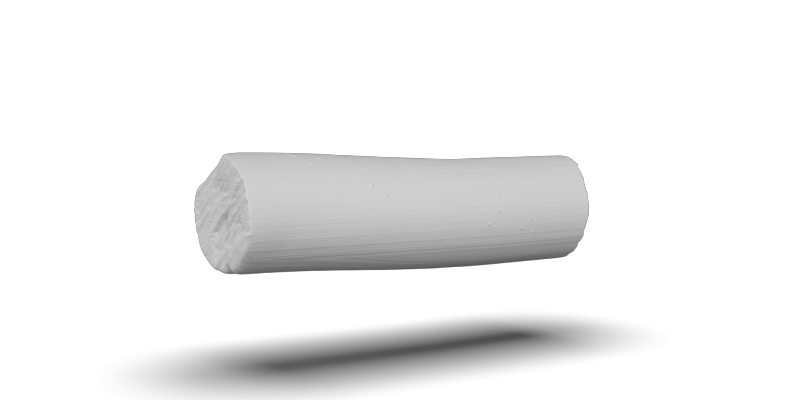

5. Zinc Oxide Desulfurizer

A reforming absorption type desulfurizer with zinc oxide as the active component. This desulfurizer has strong affinity for sulfur, high desulfurization accuracy, high sulfur capacity, high product stability, and long service life. It can effectively remove hydrogen sulfide and some organic sulfur from raw materials. It is applicable to the removal of hydrogen sulfide and some organic sulfur from various hydrogen production, synthetic methanol, synthetic ammonia and other process raw materials.

Specification: 4 * 4~10mm light yellow strip

Hydrogen Production by PSA

6, 7. 5A/13X/High Nitrogen Molecular Sieve For PSA Process

An inorganic aluminosilicate crystalline material. It has a well-developed three-dimensional pore structure and shows selective adsorption performance due to different gas molecular diameters. It is applicable to the drying and purification of hydrogen, oxygen, petroleum, natural gas and other industrial gases by PSA process.

Specifications: φ 1.5-2.5mm spherical

8. Alumina Adsorbent for PSA

A porous, highly dispersed solid material. The material can absorb all molecules to a certain extent, but will preferentially absorb strong polar molecules. It is a highly efficient desiccant with trace water; The material has large specific surface area, no expansion or crack after water absorption, high strength and easy regeneration. It is widely used in the drying of respective gas, purification of gas or liquid, catalyst and catalyst carrier, etc.

Specifications: φ 3.0-5.0mm spherical

9. Activated Carbon for PSA

A special activated carbon asorbents for PSA. The activated carbon has large CO2 adsorption capacity, easy regeneration, good strength and long service life. The adsorption is generated by the van der Waals force, which is suitable for hydrogen refining and CO2 removal, recovery and purification of CO2 in various PSA processes.

Specifications: φ 1.5-3.0mm column

10. Silica Gel Adsorbent for PSA

An amorphous highly active adsorption material. The material adopts a special production process, with large adsorption capacity, fast adsorption and decarburization, strong adsorption selectivity and high separation coefficient; The chemical property of the material is stable, non-toxic and harmless, and can be reused. It is widely used in the recovery, separation and purification of carbon dioxide gas, the production of carbon dioxide in synthetic ammonia industry, food and beverage processing industry, and the drying, moisture-proof and dehydration and refining of organic products.

Specifications: φ 2.0-5.0mm spherical

CO Adsorbent

11. CO Adsorbent

A copper based adsorbent with high CO adsorption selectivity and separation coefficient. It can be used to remove trace carbon monoxide from hydrogen for fuel cells and recover carbon monoxide from various exhaust gases.

Specification: 1/16-1/8 bar